7902 Dado Jig (26" long cut)

7902 Dado Jig (26" long cut)

Couldn't load pickup availability

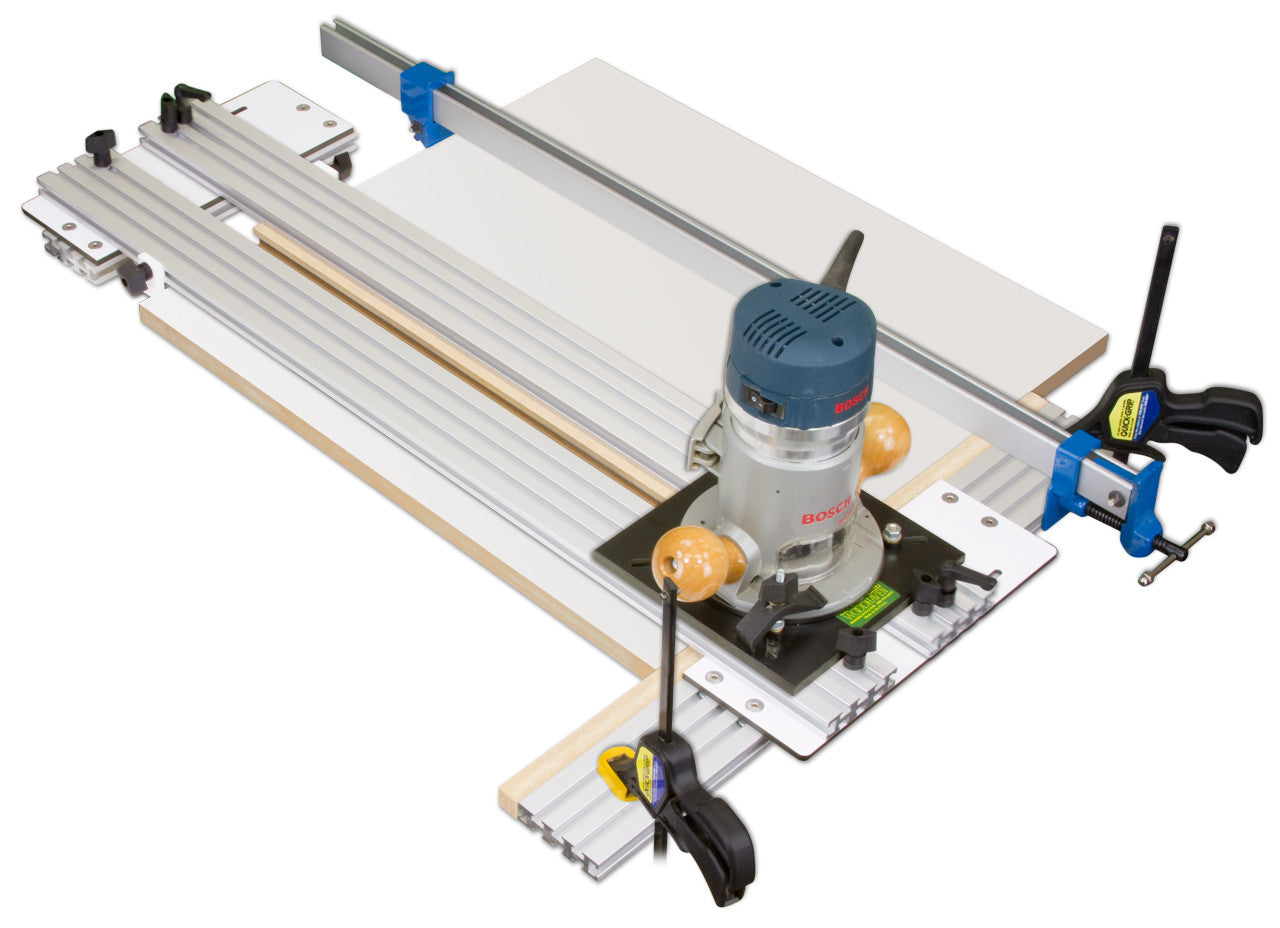

The 7902 Dado Jig cuts dadoes up to 26" long and up to 3-1/2" wide with a 1/2" bit. Simple two step process promises the quickest, easiest and most accurate dadoes you've ever made. Never be frustrated by poor fitting dadoes again! Also great for half-lap joints, flutes, sliding dovetails and more.

Built with our strong Ultra Track extrusions, Dado Jig can be clamped or bolted to your workbench or clamped to the work, clamps not included. Adjustments made with two knobs, no tools required. Includes our No-Drill router plate which has a quick attach feature that leaves your router free for other tasks.

Zero-clearance fences prevent grain lift for a clean dado and are easily replaced when worn. Length of cut controlled with easy to adjust stops. Uses standard router bits up to 3/4" diameter. We recommend our 13700 1/2" down-shear dado bit. Use a plunge router for stopped dadoes, or a fixed base router.

- Say goodbye to time consuming dado blade setups! Simple two step process promises the quickest, easiest and most accurate dadoes you've ever made. Never be frustrated by poor fitting dadoes again!

- Also great for half-lap joints, flutes, sliding dovetails and more.

- Adjustments made with two knobs, no tools required.

- Includes our No-Drill router plate which has a quick attach feature that leaves your router free for other tasks.

- Router & clamps not included

All products are Made in the USA and have a lifetime guarantee against defects in material or workmanship! For product questions or to quote shipping outside the continental US call 800-344-6657 or email info@Woodhaven.com

I wish you had a close-up video of setting up the 1/4 MDF subfence, I bought this jig a while back, but I am just starting to use it. I had to turn the fences around because I did something wrong. going to try it again, the cutter will not cut close flush to the subfence. I am disappointed somewhat with this part of the subfence

Great product it preformed as expected

I used this jig to mortise stair stringers, it worked beyond expectations and I am happy with my purchase.

I'm a retired wood shop teacher and I value every penny I have. I was going to make the same jig out of wood. But even if I sealed the wood, if it warped or twisted at all, the jig would be useless. Then I thought of buying extrusions and making it out of metal. The difference in cost to build or buy wasn't much, so I decided to buy the Woodhaven.

And I'm glad I did. It will last forever.

However, I'm using a router bushing in my router instead of the router plate that comes with the jig.

Why?

After assembling the jig before you begin cutting dados you have to trim the MDF that the rails sit on. The MDF is called a "sub fence" and after they're trimmed they will become the "cut lines". Their edges will protrude from the rail and the bit will make its cut along their edges. To cut a dado you'll set the edge of the "sub fence" on your dado line. Moving in a circular motion after cutting that line you'll cut the other edge of the dado.

*See Woodhaven's video.

The Problem:

On the bottom of Woodhaven's router plate is a "guide". Its a rectangular piece of Phenolic. It creates "stand off" so your bit doesn't cut the rail.

As I've stated, the final step in assembly is to trim the "sub fence". In doing so the "sub fence" will become the bit's "cut line" . This line is in relation to the "stand off" created by the router plate's rectangular guide.

The problem created by the jig plate is that once you remove the router from the plate and later re-install it, the bit will never be in exactly the same spot as it was when you first trimmed the "sub fence". You'll never get it exactly centered again. In fact it probably wasn't exactly centered in the first place.

And now the distance between the "sub fence" and the bit won't be the same as it was when you first trimmed it, resulting in the "sub fence" no longer being an accurate cut line.

The Solution:

By using a router bushing you will eliminate that problem. The bushing will run along the rail and its "stand off" will be created by the size of the bit and bushing you use. It will be consistent each time you use it. But the jig will be "married" to that size bushing and bit. If you change either of those, the new bit may recut the "sub fence".

A 1/2" bit's bushing wall is very thin: approximately 13/32". A 5/8" bushing's wall is 17/32". There's also clearance between the bit's cutter and the inside of the bushing's wall. Adding the clearance between the bit's cutter's edge to the thickness of the bushing's wall is the total "stand off". After being trimmed the "sub fence" will protrude that amount from the rail.

Using a 3/8" bit and a 5/8" bushing will give you more "stand off" than any combination of bit and bushing And result in the greatest amount of MDF protruding beyond the rail. Using a 1/2" bit with either the 1/2" bushing or the 5/8" bushing will result in less "stand off". I use a 3/8" bit and 5/8" bushing. It produces enough "stand off" to allow the "sub fence" to protrude enough so I can easily see the "cut line".

Consistency:

Because the wall's thickness never changes, each time you use the same bushing with the same bit, its cutting edge will always be duplicated. It will consistently run true to the "sub fence's" edge. The cut line will always be accurate. Good Luck and I hope I explained this well.